In today’s fast-paced industrial world, one-size-fits-all equipment often falls short. That’s why custom material handling solutions and electric tow tugs are rapidly becoming essential tools for businesses striving for safer, more efficient operations. Whether you're moving sheet materials, transporting heavy loads, or navigating tight production environments, tailored equipment ensures you get the performance and productivity you need—without compromise.

Why Custom Material Handling Solutions Matter

Every industry has unique challenges—limited space, awkward loads, safety concerns, or high-volume demands. Off-the-shelf handling equipment often isn't optimized for these realities, leading to inefficiencies, worker strain, or even downtime.

That’s where customized material handling systems come in. They are engineered around your specific needs, delivering seamless integration into your workflow and real ROI through:

- Improved safety by reducing manual handling and the risk of injury

- Optimized load movement that saves time and labour

- Adaptability to changing processes or specialized materials

- Enhanced productivity through ergonomically designed systems

From bespoke trolleys for sheet materials to tailor-made electric tug solutions, custom builds ensure your equipment works for you—not the other way around.

The Rise of Electric Tow Tugs in Modern Industry

Electric tow tugs are transforming how industries move loads. Quiet, powerful, and easy to operate, they remove the need for forklifts or manual pushing. But to unlock their full potential, customization is key.

Off-the-shelf tugs may not align with your unique load type, weight, or operating environment. A custom electric tow tug takes these variables into account—motor power, hitch design, battery life, and operator ergonomics—so your team can move materials efficiently, safely, and with minimal effort.

Common applications include:

- Moving heavy machinery or parts across production lines

- Towing multiple trolleys in warehouses

- Transporting bulky sheet goods in manufacturing

- Handling sensitive materials in cleanroom environments

With the right customisation, electric tugs become indispensable assets in lean manufacturing and logistics strategies.

What to Look for in a Custom Material Handling Partner

Not all custom solutions are created equal. When choosing a provider for custom material handling equipment or electric tow tugs, look for:

- Proven design experience with bespoke equipment

- In-house engineering capabilities for fast prototyping

- Tailored branding and sizing to match your facility or process

- After-sales support and service to keep things running smoothly

A partner that understands your workflow and adapts their solutions accordingly will save you time, money, and operational headaches.

Invest in Equipment That Works For You

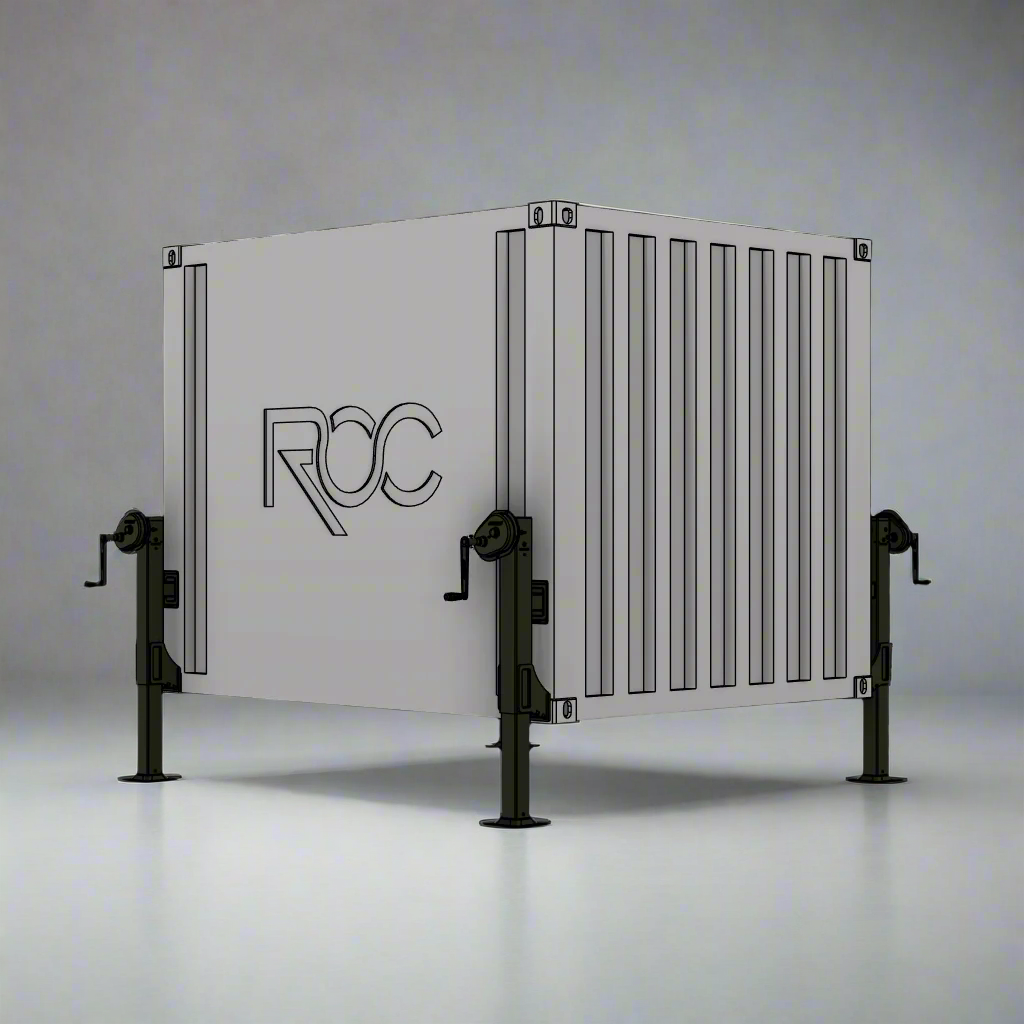

At ROC, we specialise in Industrial Trailers, Application Trolleys, Stainless Steel Trolleys and E-Drive Trolleys as well as purpose-built solutions that match your exact requirements—including size, load type, branding, and colour. Whether you're looking to improve safety, increase throughput, or future-proof your facility, we deliver custom handling systems and electric towing solutions that give you the edge.

Let’s design something that fits your process—not the other way around.

+44(0)1296 438200

sales@roc-uk.co.uk